Production processes

This process includes two main phases: the color matching and the production on industrial scale.

Color matching

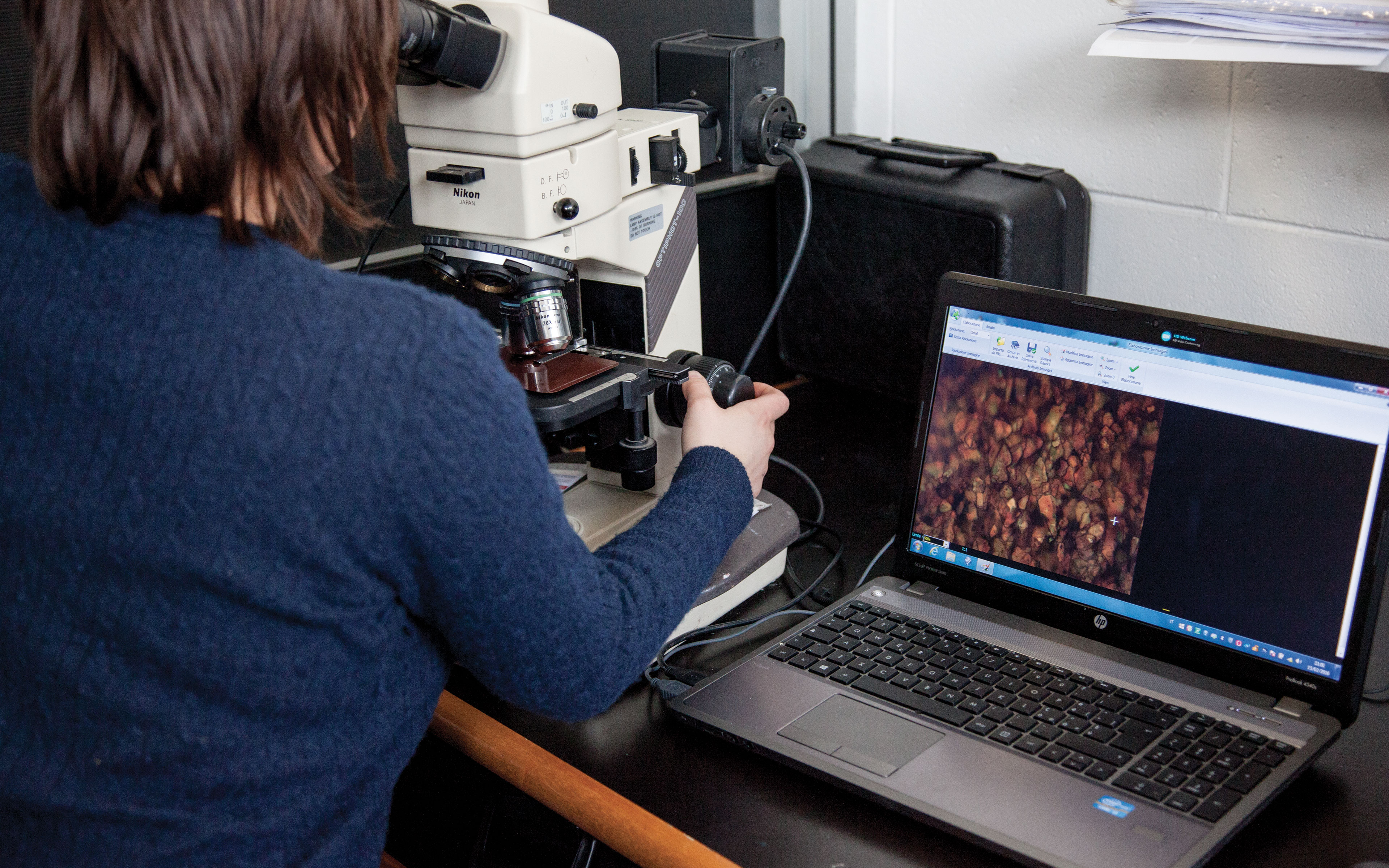

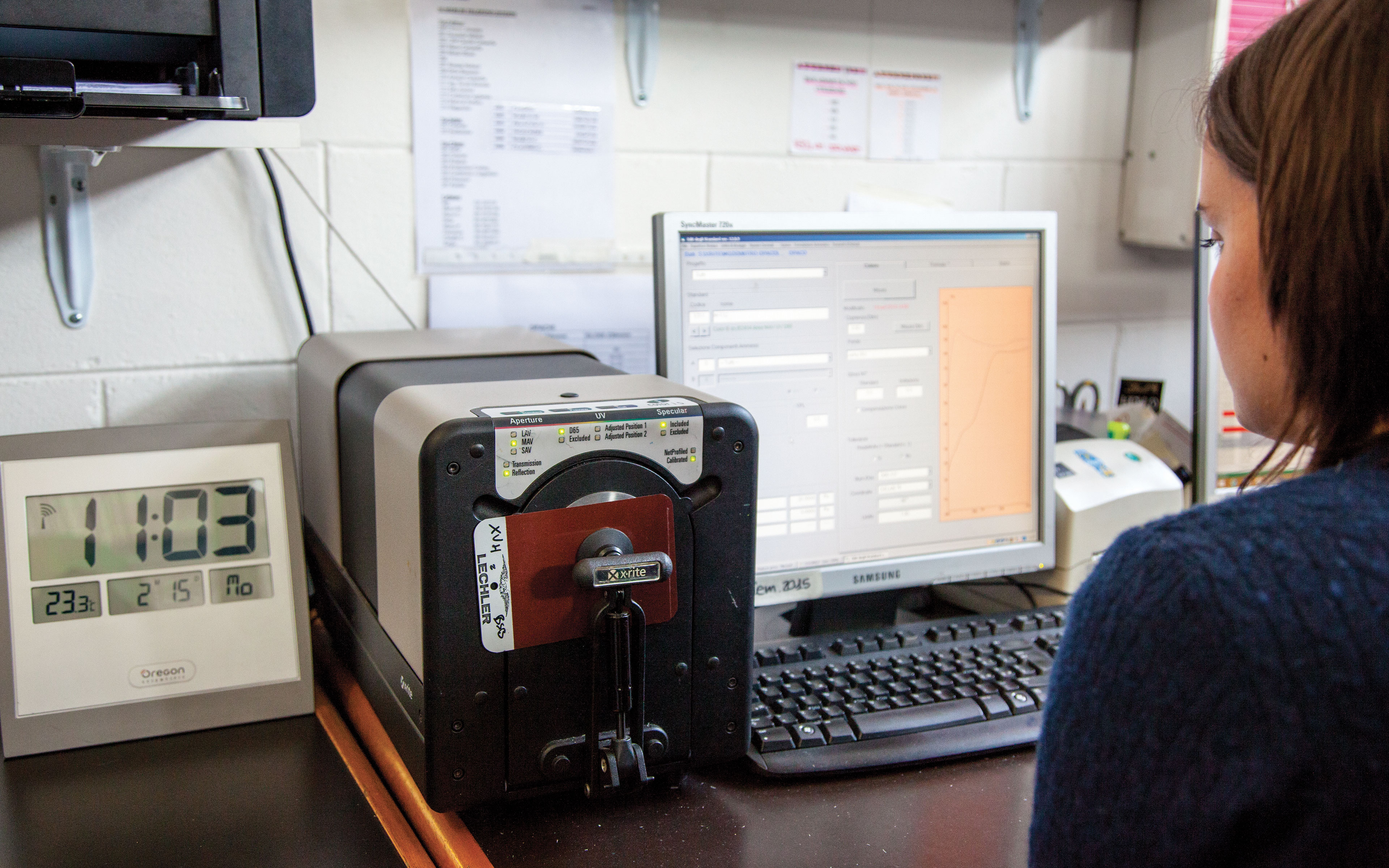

Color matching takes place in our two laboratories where our colorists, who are all professionals with unique skills and knowledge, reproduce the customer’s original reference on paper, using either customer’s original paint or one of our own painting systems, which we put at their disposal.

We provide our colorists with cutting-edge electronic devices for color research and analysis, but the last decision belongs to our colorists, using the human eyes as the ultimate tool of color matching.

The outcome of color matching activity is then submitted to customer approval before the production on industrial scale commences.

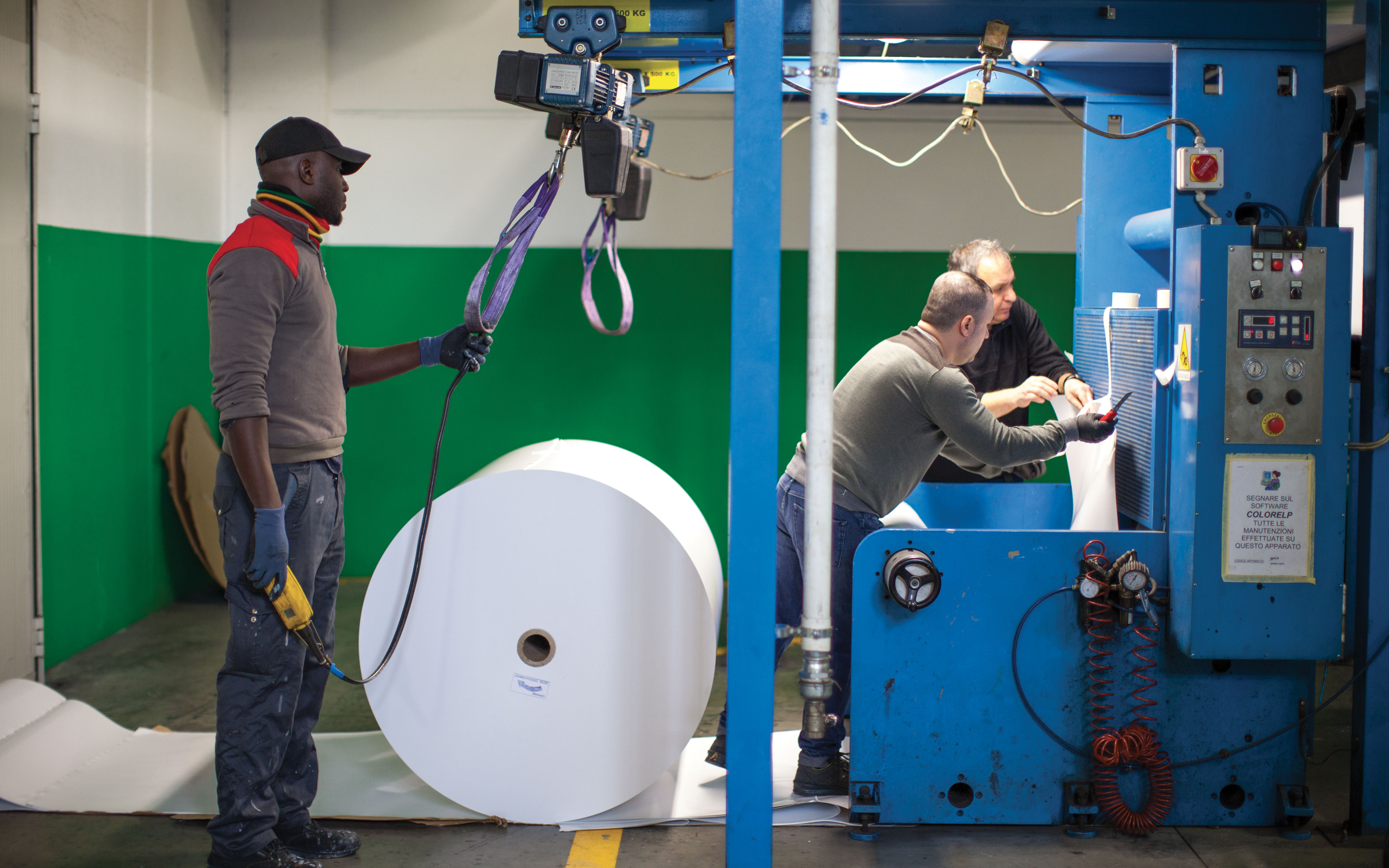

Scale production

The spraying system fills a generational gap. It is an innovative system, specifically developed with reference to metal colors. It is therefore the best system for Car Refinishing customers, who deem the color sample not as a simple marketing accessory, but as a proper working tool, able to determine the success of a product line and essential for body shops activity.

The final product, either coated or sprayed, is finally submitted to the customer, who checks it against the lab match and the original reference. Samples from different parts of production are compared in order to check the consistency of the whole production run.